Tungsten Woven Wire Mesh

Price 50 INR/ Unit

Tungsten Woven Wire Mesh Specification

- Length

- 1 meter - 100 meter (rolls or cut pieces)

- Aperture

- 0.025 mm - 5 mm

- Surface Treatment

- Uncoated

- Wire Gauge

- 10-400 mesh

- Hole Shape

- Square

- Product Type

- Woven Wire Mesh

- Mesh Type

- Woven

- Mesh Style

- Plain weave, Twilled weave

- Material

- High purity Tungsten (>99.95%)

- Alloy

- Pure Tungsten

- Application

- Filtration, Sieving, Electronics, Aerospace, Medical, Chemical processing

- Dimensions

- Custom sizes available

- Wire Diameter

- 0.02 mm - 0.5 mm

- Weight

- Depends on size and wire diameter

- Color

- Metallic grey

About Tungsten Woven Wire Mesh

Tungsten is an extremely hard metallic element with an extremely high melting point and corrosion resistance in many harsh environments. Tungsten is resistant to oxidation attack and corrosion in acidic and alkaline media and is used in the elevated temperature filtration applications. Tungsten offers excellent high temperature mechanical characteristics and smallest coefficient of thermal expansion among all metals. The mesh itself will remain strong and stable with a high percentage of open area. Different patterns such as plain weave, twilled weave, and plain dutch weave are made on these types of weaving looms.Superior Heat and Chemical Resistance

Tungsten Woven Wire Mesh is uniquely engineered to maintain stability at extreme temperatures, up to 3000C, and resists most acids and alkalis. Its high purity and dense structure ensure dependable use in environments where other metals might fail, making it indispensable for critical industrial filtration, sieving, and separation processes.

Versatile Customization and Applications

With mesh counts from 10 to 400 and customizable dimensions, this mesh is adaptable for various technical needs. It is offered in plain and twilled weaves, supporting specific application requirements in sectors such as medical, chemical, aerospace, and electronics. The mesh can be supplied as rolls, cut sheets, or tailored to precise client specifications.

FAQs of Tungsten Woven Wire Mesh:

Q: How is tungsten woven wire mesh manufactured?

A: Tungsten woven wire mesh is produced by weaving high-purity tungsten wires in plain or twilled patterns using precision looms. This process results in a uniform structure with specified mesh sizes and wire diameters, ensuring stringent quality for applications requiring high performance and reliability.Q: What are the primary uses of tungsten woven wire mesh?

A: This mesh is widely used for high-temperature filtration, precise sieving in laboratories, shielding in electronic devices, aerospace components, and in chemical processing equipment where resistance to harsh environments and stability are vital.Q: Where can I utilize tungsten woven wire mesh effectively?

A: The mesh is ideal for environments exposed to high temperatures or corrosive chemicals, such as chemical plants, electronic manufacturing, aerospace engineering, and advanced medical devices, due to its durability and chemical inertness.Q: What are the benefits of using tungsten woven wire mesh over other metal meshes?

A: Tungsten offers superior temperature and corrosion resistance, high tensile strength, and maintains integrity in extreme conditions. These characteristics make it preferable for tasks where other metals, such as stainless steel or nickel, might degrade.Q: How should tungsten woven wire mesh be handled and stored?

A: It is recommended to handle the mesh with care to avoid deformation due to its fine structure. For storage, keep the mesh in its standard packagingrolls or sheets secured within wooden cases or palletsto protect from contamination and physical damage.Q: What is the customization process for dimensions and mesh type?

A: Clients can request specific mesh counts, aperture sizes, wire diameters, and dimensions. The manufacturer will tailor the product to your needs, offering options like rolls, cut-to-size sheets, and both plain and twilled weave structures.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Woven Wire Mesh Material Category

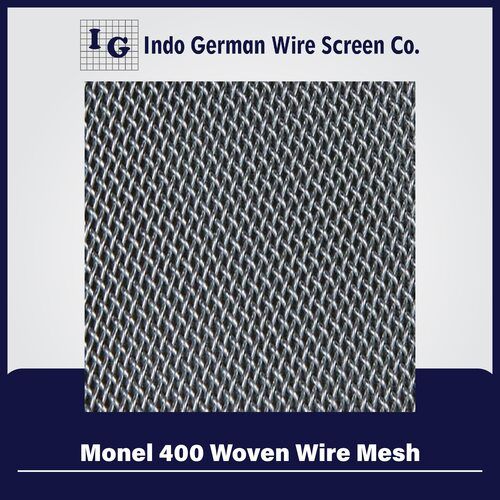

Monel 400 Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Other

Product Type : Wire Mesh

Color : Gray

Surface Treatment : Coated

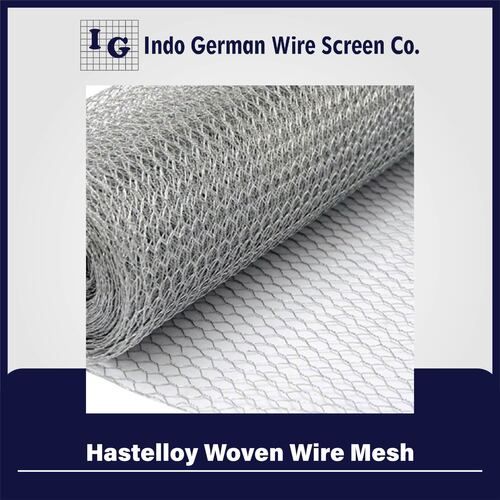

Hastelloy Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Other

Product Type : Wire Mesh

Color : Silver

Surface Treatment : Coated

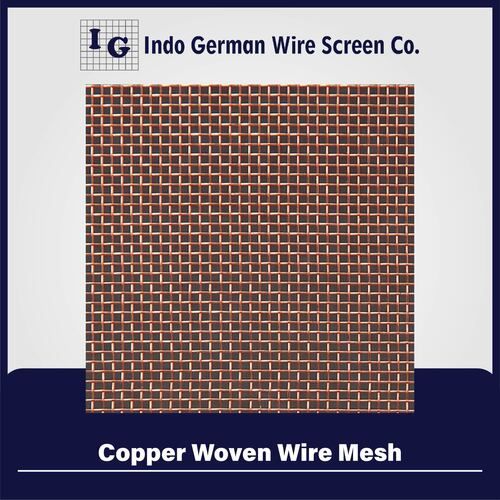

Copper Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Other

Product Type : Wire Mesh

Color : Copper

Surface Treatment : Coated

Nickel Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Other, Filtration, Battery Electrode, Chemical Processing, Laboratory, Aerospace, Electronics

Product Type : Other, Woven Wire Mesh

Color : Silver Grey

Surface Treatment : Other, Bright Annealed

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry