Nickel Expanded Wire Mesh

Price 50 INR/ Unit

MOQ : 1 Unit

Nickel Expanded Wire Mesh Specification

- Hole Shape

- Diamond

- Length

- 2000 mm

- Aperture

- 3 mm

- Surface Treatment

- Polished

- Wire Gauge

- 20 SWG

- Product Type

- Expanded Mesh

- Mesh Type

- Heavy Duty

- Mesh Style

- Expanded

- Material

- Nickel

- Alloy

- Nickel 200

- Application

- Filtration, Battery Electrode, Chemical Processing

- Dimensions

- 1000 mm x 2000 mm

- Wire Diameter

- 0.9 mm

- Weight

- 6.5 kg/Sheet

- Color

- Silver

- Corrosion Resistance

- Excellent

- Elongation

- 40%

- Packing Type

- Wooden Case

- Standard

- ASTM B122

- Thickness

- 1 mm

- Edge Type

- Plain Edge

- Custom Sizes

- Available

- Yield Strength

- 300 MPa

- Open Area Percentage

- 60%

- Max Working Temperature

- 400°C

About Nickel Expanded Wire Mesh

Nickel is a silvery-white hard metal whose strength, ductility and resistance to heat and corrosion make it exceptionally useful for the manufacturing of a wide range of materials from wires to coins to military equipment. Nickel is woven using high purity nickel wire and is mostly favoured in corrosive environments such as filtration of liquids, gas, etc. Nickel Expanded Wire mesh specification the most versatile mesh uniformly slit and stretched, forming a diamond pattern of openings in the finished sheet and has numerous patterns by using the different moulds. Expanded Mesh or Expanded Metal Mesh is manufactured within a variety of specifications using different metals to suit a wide range of applications both as filter elements and filter support.Advanced Material Performance

Constructed from nickel, this expanded wire mesh is designed for resilience. Its excellent corrosion resistance ensures longevity in aggressive chemical environments, while the materials 40% elongation and 300 MPa yield strength enable flexibility and strength. The 1 mm thickness paired with a 0.9 mm wire diameter guarantees robust mechanical properties.

Versatile Industrial Applications

This mesh is highly favored for use in filtration systems, battery electrodes, and chemical processing owing to its efficient 60% open area and secure, diamond-patterned apertures. Its stability at temperatures up to 400C makes it ideal for harsh and high-demand operations, maintaining both performance and structure under stress.

Customization and Packaging

In recognition of diverse industrial requirements, custom sizes are available alongside the standard 1000 mm x 2000 mm sheets. The product is packed in sturdy wooden cases to ensure safe transit and delivery. Adherence to ASTM B122 standard and polished finishing further enhance quality and service.

FAQs of Nickel Expanded Wire Mesh:

Q: How can Nickel Expanded Wire Mesh be utilized in battery electrode manufacturing?

A: Nickel Expanded Wire Mesh, with high conductivity and corrosion resistance, is ideal for battery electrode applications. It serves as a supportive matrix, improving electron flow and ensuring consistent performance even under demanding electrochemical conditions.Q: What are the main benefits of choosing heavy-duty nickel mesh for filtration purposes?

A: Heavy-duty nickel mesh with a 60% open area allows efficient fluid or air passage while retaining particulates. Its excellent corrosion resistance and 300 MPa yield strength make it a reliable, long-lasting solution for filtration in harsh chemical environments.Q: When should I opt for custom-sized nickel expanded mesh rather than standard dimensions?

A: Custom sizes should be chosen when your application requires non-standard dimensions, unique fitting needs, or specialized installations. Customization ensures optimal coverage, fit, and performance in unique equipment or system designs.Q: Where is this nickel wire mesh typically installed for chemical processing?

A: This mesh is commonly integrated into reactor vessels, filtration units, and separators within chemical plants where resistance to acidic or alkaline corrosion and high thermal stability are crucial for safe and effective processing.Q: What process is used to create the expanded mesh structure, and how does it benefit performance?

A: The mesh is manufactured by slitting and stretching nickel sheets, forming diamond-shaped apertures without waste. This process imparts strength, rigidity, and a uniform structure, reducing weak points and ensuring stable performance under mechanical stress.Q: How does the polished surface treatment improve the wire meshs functionality?

A: The polished finish reduces surface roughness, minimizing contaminant build-up and facilitating easy cleaning. It also enhances corrosion resistance by smoothing out imperfections where corrosive agents might accumulate.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Expanded Mesh Category

Brass Expanded Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other, Brass

Mesh Style : Expanded Mesh

Product Type : Wire Mesh

Color : Golden

Inconel Expanded Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other, Inconel (NickelChromium Alloy)

Mesh Style : Other , Expanded Metal Mesh

Product Type : Other, Expanded Wire Mesh

Color : Silver Grey

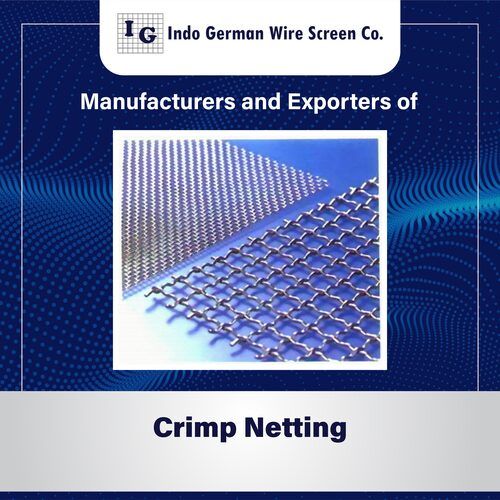

Crimp Netting

Material : Stainless Steel

Mesh Style : Other , Crimped Mesh

Product Type : Wire Mesh

Color : Sliver

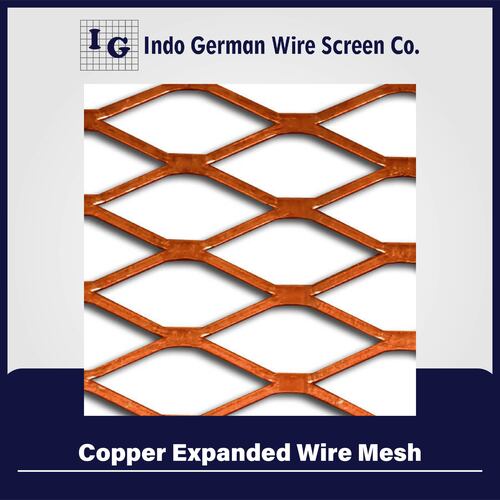

Copper Expanded Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Copper

Mesh Style : Expanded Mesh

Product Type : Wire Mesh

Color : Copper

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry