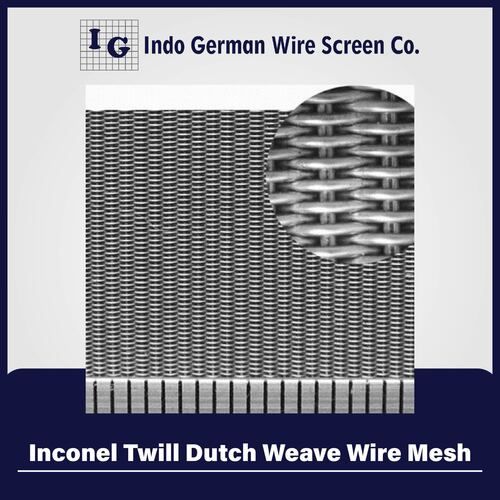

Inconel Twill Dutch Weave Wire Mesh

Price 50 INR/ Unit

Inconel Twill Dutch Weave Wire Mesh Specification

- Surface Treatment

- Coated

- Product Type

- Wire Mesh

- Mesh Style

- Plain Mesh

- Material

- Inconel

- Application

- Other

- Color

- Gray

Inconel Twill Dutch Weave Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Inconel Twill Dutch Weave Wire Mesh

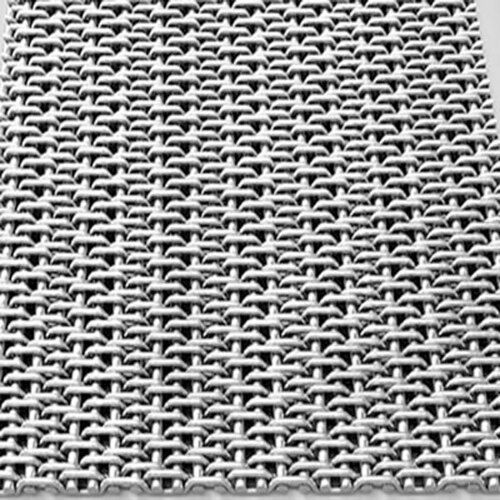

Inconel is a mixture of nickel-chromium alloy and aluminium or molybdenum is added into Inconel as per requirement and grade. Inconel are useful in a wide range of industrial applications as they are heat resistant, corrosion resistant, and they tend to provide great productivity and service even after prolonged use.This type of weave is made up of a limited number of warp wires interwoven with the maximum number of weft wires, thereby forming a firm and strong cloth. The Inconel Twill Dutch weave has a high filtering level and high pressure load resistance.

We offer an exclusive range ofInconel Twill Dutch Weave Wire Meshat unmatched quality and market leading prices.

Superior Material Strength

Crafted from Inconel, this wire mesh provides unmatched strength, resilience against extreme temperatures, and resistance to corrosive environments. Its advanced properties ensure long-term operation, even under harsh industrial conditions.

Precision Weaving Technique

Utilizing twill dutch weave methods, this mesh achieves fine filtration and uniform aperture sizing. The coated surface treatment further safeguards the mesh against wear, enhancing its functional performance and lifespan.

FAQs of Inconel Twill Dutch Weave Wire Mesh:

Q: How is Inconel Twill Dutch Weave Wire Mesh manufactured in India?

A: In India, this wire mesh is crafted using advanced twill dutch weaving techniques from Inconel alloy. The mesh is then coated to improve both its durability and resistance to corrosive agents, ensuring high-quality standards for export and supply.Q: What advantages does the coated surface offer for Inconel wire mesh?

A: The coated surface treatment significantly enhances the meshs resistance to chemical damage, oxidation, and abrasion. This ensures a longer service life and reliability, especially in demanding industrial environments.Q: Where is Inconel Twill Dutch Weave Wire Mesh primarily used?

A: This mesh is popular in industries such as chemical processing, aerospace, and energy. Its robust properties and precise filtration capabilities make it suitable for critical applications that require both strength and accuracy.Q: When should I consider using gray, plain mesh style Inconel wire mesh for my application?

A: Choose Inconel wire mesh with a plain mesh style and gray finish when your application demands superior strength, temperature resistance, and corrosion protection, particularly in filtration and separation processes.Q: What is the process behind the twill dutch weave style in Inconel wire mesh?

A: The twill dutch weave process involves interlacing Inconel wires in a pattern that creates a tightly woven, fine mesh. This technique delivers consistent aperture sizes, making it ideal for precision filtration tasks.Q: How can using Inconel wire mesh benefit my industrial operations?

A: Using Inconel wire mesh ensures durability, operational reliability, and reduced maintenance due to its exceptional heat and corrosion resistance. Its robust construction helps maximize product quality and process efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Twill Dutch Weave Wire Mesh Category

Steel Twill Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Length : 30 Meter

Color : Gray

Product Type : Wire Mesh

Alloy : Stainless Steel 304

Monel 400 Twill Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Length : 30 Meter (m)

Color : Gray

Product Type : Wire Mesh

Alloy : Monel 400

Titanium Twill Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Length : 30 m or as required

Color : Gray

Product Type : Wire Mesh

Alloy : Pure Grade 2, Grade 5 Titanium

Hastelloy Twill Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Length : Available in rolls of up to 30 meters or as required

Color : Gray

Product Type : Wire Mesh

Alloy : Hastelloy C276 (NickelChromiumMolybdenum alloy)

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry