Hastelloy Expanded Wire Mesh

Price 50 INR/ Unit

Hastelloy Expanded Wire Mesh Specification

- Surface Treatment

- Coated

- Aperture

- Typically 3 mm 50 mm

- Length

- Standard rolls of 6 m, can be customized

- Wire Gauge

- As per requirement (typically 1 mm - 4 mm)

- Hole Shape

- Diamond

- Product Type

- Wire Mesh

- Mesh Type

- Expanded

- Mesh Style

- Expanded Mesh

- Material

- Other

- Alloy

- Hastelloy C276, C22, B3, G30 (as specified)

- Application

- Other

- Dimensions

- Custom sizes; standard width: 1 m, 1.2 m, 2 m

- Wire Diameter

- 1 mm 4 mm (customizable)

- Weight

- Depends on thickness and dimensions; generally 5 15 kg/m

- Color

- Silver-grey (metallic)

- Temperature Range

- Resistant up to 1100C

- Open Area

- Up to 70%

- Strand Width

- Typically 1.5 mm 6 mm

- MOQ

- 10 m or as per order

- Packing

- Rolls, sheets, or customized packing

- Manufacturing Process

- Expanded and flattened from solid Hastelloy sheet

- Edge Type

- Bonded or open edges per order

- Corrosion Resistance

- Excellent; suitable for aggressive chemicals

Hastelloy Expanded Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Hastelloy Expanded Wire Mesh

Hastelloy is a corrosion resistant alloy and has a higher work hardening rate than the austenitic stainless steels which should be taken into consideration. Hastelloy has a smooth surface and has an excellent aesthetic appearance and will not easily fray or unravel, is stable and rigid. Hastelloy construction provides durable and strong packing that can withstand the harshest environments.Hastelloy Expanded Wire mesh specification the most versatile mesh uniformly slit and stretched, forming a diamond pattern of openings in the finished sheet and has numerous patterns by using the different molds.Superior Corrosion Resistance

Hastelloy Expanded Wire Mesh offers outstanding resistance to corrosion, especially in environments involving aggressive chemicals and acids. Its durable nature makes it a prime choice for industries such as chemical processing, pharmaceuticals, and marine engineering, where exposure to harsh agents is common.

Customizable and Versatile Applications

This mesh is designed for versatility, with customizable strand width, aperture, wire diameter, and overall dimensions. Users can select mesh configurations and packing methods tailored to specific requirements, supporting a wide array of industrial and protective applications.

Engineered for Extreme Conditions

With a temperature resistance up to 1100C, Hastelloy Expanded Wire Mesh maintains its integrity and mechanical strength in extreme heat. This makes it particularly suitable for high-temperature filtration, insulation, and protective screens in demanding operational environments.

FAQs of Hastelloy Expanded Wire Mesh:

Q: How is Hastelloy Expanded Wire Mesh manufactured?

A: Hastelloy Expanded Wire Mesh is produced by expanding and flattening solid Hastelloy sheets. This process creates a strong, uniform mesh without welding or weaving, resulting in consistent openings and a seamless structure.Q: What benefits does the excellent corrosion resistance of Hastelloy mesh provide?

A: The outstanding corrosion resistance of Hastelloy ensures reliable performance in environments with aggressive chemicals, acids, and high humidity. This increases product longevity and reduces maintenance requirements, making it ideal for chemical plants and offshore installations.Q: When should I choose bonded versus open edges for my mesh order?

A: Bonded edges provide reinforced borders that prevent unraveling and enhance structural rigidity, best for applications where stability is crucial. Open edges are suitable when the mesh will be further processed or fitted into frames, offering design flexibility.Q: Where can Hastelloy Expanded Wire Mesh be used effectively?

A: This mesh is widely used in chemical processing, petrochemicals, HVAC, pharmaceuticals, filtration units, and protective screens. Its adaptability to harsh environments makes it a staple in industrial, marine, and high-temperature settings.Q: What is the minimum order quantity and available packing options?

A: The minimum order quantity for Hastelloy Expanded Wire Mesh is generally 10 m, though custom orders may be discussed. Packing options include rolls, flat sheets, and tailored packing solutions to best suit transportation and end-use requirements.Q: How can the mesh be customized to fit my project requirements?

A: You can specify dimensions such as strand width, aperture size, wire diameter, length, and width, as well as choose the desired alloy grade, color finish, and hole shape. Manufacturers in India offer custom sizes and configurations to meet diverse industrial demands.Q: What makes Hastelloy Expanded Mesh preferable over conventional mesh products?

A: Its single-piece structure, absence of welds, adaptability in design, exceptional corrosion and heat resistance, and availability in various alloys make Hastelloy Expanded Mesh a superior choice for demanding and specialized industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Expanded Mesh Category

Brass Expanded Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Coated

Color : Golden

Material : Other, Brass

Mesh Type : Other , Expanded

Inconel Expanded Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Other, Annealed, Pickled

Color : Silver Grey

Material : Other, Inconel (NickelChromium Alloy)

Mesh Type : Other , Heavy and Light Duty

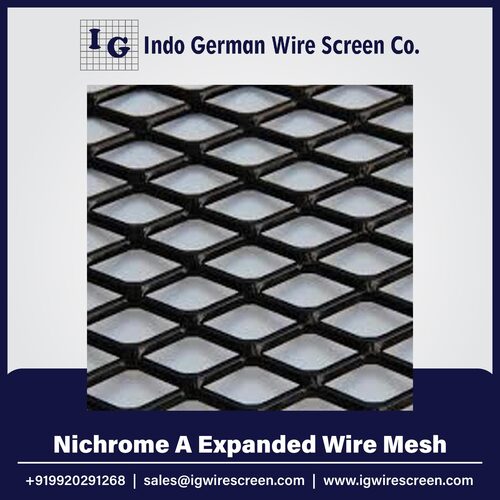

Nichrome A Expanded Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Other, Uncoated

Color : Silver

Material : Other, Nichrome A

Mesh Type : Other , Open Mesh

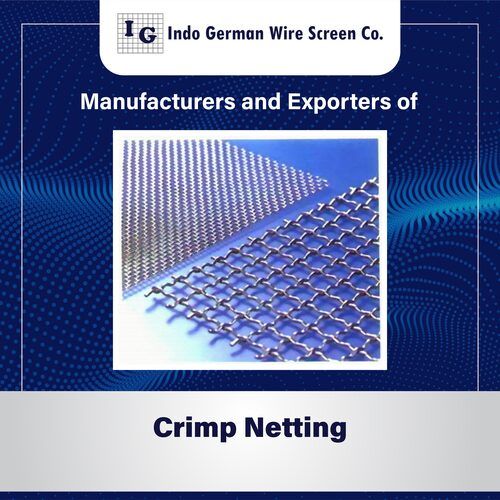

Crimp Netting

Surface Treatment : Other, Galvanized or Stainless Steel Finish

Color : Sliver

Material : Stainless Steel

Mesh Type : Steel Wire Mesh

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry