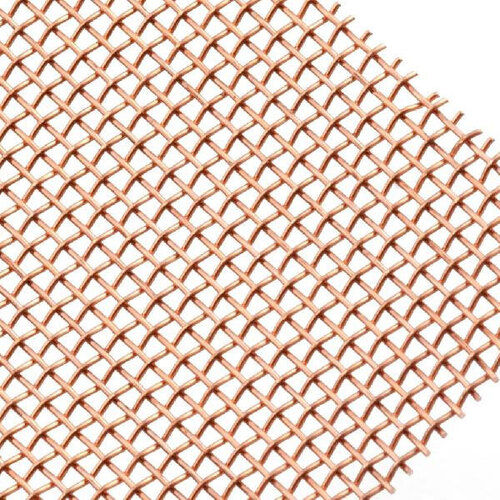

Copper Plain Weave Wire Mesh

Price 50 INR/ Unit

Copper Plain Weave Wire Mesh Specification

- Length

- 30 meters (standard roll)

- Surface Treatment

- Bright and Smooth

- Wire Gauge

- 10 to 100 mesh

- Aperture

- 0.15 mm to 2 mm

- Hole Shape

- Square

- Product Type

- Wire Mesh

- Mesh Type

- Woven Mesh

- Mesh Style

- Plain Weave

- Material

- 99% Pure Copper

- Alloy

- C11000 (Pure Copper)

- Application

- Filtration, Screening, EMI/RFI Shielding, Decorative Uses, Chemical Processing

- Dimensions

- Customizable width up to 1.2 meters

- Wire Diameter

- 0.08 mm to 2 mm

- Weight

- Varies by specification, ~0.45 kg/m (for standard mesh)

- Color

- Copper Red

- Corrosion Resistance

- Excellent against water and air

- Packing Type

- Rolls or cut pieces in wooden cases

- Opening Rate

- 70% - 85% (depends on mesh count and wire diameter)

- Electrical Conductivity

- High (conducts electricity efficiently)

- Temperature Resistance

- Up to 200°C

- Minimum Order Quantity

- 10 Square Meters

- Edge Type

- Plain / Selvage

- Usage Environment

- Indoor and Outdoor

About Copper Plain Weave Wire Mesh

Copper is ductile, malleable and has high thermal and electrical conductivity. Copper wire netting is popularly used as RFI shielding, in Faraday Cages, in roofing, in HVAC and in numerous electrical-based applications. Copper wire mesh is resistant to atmospheric corrosion but attacked by oxidizing agents such as nitric acid, ferric chloride, cyanides, and ammonia acid compounds. Copper wire mesh when exposed to the atmosphere it will naturally develop a thin green layer, known as patina. Copper wire mesh is anti-sparkling in nature, has low tensile strength, is deprived of wear and tears and they darken after some time period. Copper Netting Wire Mesh exhibits a white or silver easy to clean surface, where either side is usable and the pattern looks the same.Usually the finer Copper Plain Weave Wire Mesh weaves are most commonly used in petrochemical and food processing, chemical, plastic production houses, on the other hand, coarser Copper Plain Weave Wire Mesh weaves are used for dewatering, sizing, filter cloth and extruding applications. Copper Plain Weave Wire Meshes are available with apertures from 10.7 mm (2 mesh) to 0.05 mm (325 mesh).

Superior Resistance and Versatility

Made from pure copper alloy (C11000), this wire mesh offers high corrosion resistance, making it ideal for use in both challenging outdoor and controlled indoor environments. With robust temperature endurance up to 200C and excellent conductivity, it caters to demanding industrial and decorative requirements alike.

Customizable to Suit Every Project

Available in a wide range of mesh sizes, apertures, and customizable widths, the Copper Plain Weave Wire Mesh fits various filtration, shielding, and architectural needs. Rolls are conveniently packed in sturdy wooden cases, ensuring safe transport and handling.

FAQs of Copper Plain Weave Wire Mesh:

Q: How is Copper Plain Weave Wire Mesh used in EMI/RFI shielding applications?

A: Copper wire meshs high electrical conductivity makes it an effective material for blocking electromagnetic and radio frequency interference (EMI/RFI), commonly used to shield sensitive electronic equipment, cables, and rooms.Q: What are the benefits of using this mesh for filtration and screening?

A: With customizable aperture sizes and a high opening rate (70%85%), the mesh allows efficient passage of air or fluids while trapping unwanted particles, making it suitable for precision filtration and screening tasks in various industries.Q: What process is followed for packing and delivery?

A: The mesh is supplied in rolls or as cut pieces, and packed securely in wooden cases to prevent damage during transit, facilitating safe delivery whether ordered domestically or internationally.Q: Where can this copper wire mesh be installed?

A: Thanks to its durable and corrosion-resistant design, the mesh can be installed both indoors and outdoors, performing reliably in diverse climatic conditions ranging from industrial plants to architectural features.Q: When should I consider plain versus selvage edge for my application?

A: Plain edges are standard and suitable for most general uses, while selvage edges provide added strength and are recommended for applications where mesh integrity and resistance to unraveling are critical.Q: What is the minimum order quantity and can I order custom sizes?

A: The minimum order quantity is 10 square meters. Widths can be customized up to 1.2 meters, and mesh configuration, wire diameter, and aperture can be tailored to specific project needs.Q: How does the surface treatment of the wire mesh enhance its performance?

A: The bright and smooth surface not only boosts its visual appeal for decorative uses, but also minimizes oxidation and makes cleaning easy, aiding longevity and operational efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Stainless Steel Wire Mesh Category

Wire Mesh For Steel Industry

Mesh Type : Aluminum Wire Mesh

Mesh Style : Other , Woven

Material : Stainless Steel

Dimensions : 1.22 m x 30 m

Weight : Approx. 25 kg per Roll

Surface Treatment : Galvanized

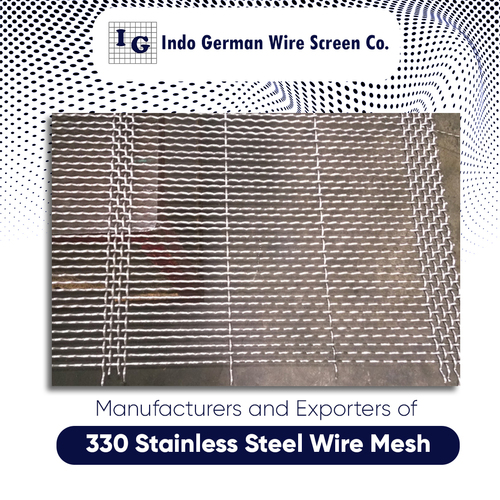

330 Stainless Steel Wire Mesh

Mesh Type : Steel Wire Mesh

Mesh Style : Other , Woven

Material : Stainless Steel

Dimensions : Custom Sizes Available

Weight : As per size and specification

Surface Treatment : Polished

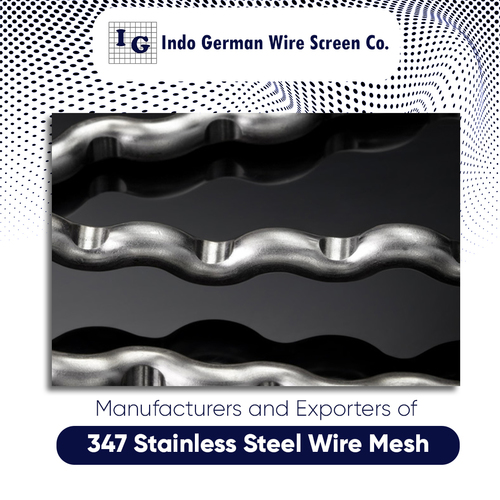

347 Stainless Steel Wire Mesh

Mesh Type : Steel Wire Mesh

Mesh Style : Other , Woven

Material : Stainless Steel

Dimensions : Width: 1 meter to 2 meters (custom available)

Weight : Depends on mesh count and wire diameter

Surface Treatment : Other, Annealed or Uncoated

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry