314 Stainless Steel Perforated Sheets

Price 50 INR/ Unit

314 Stainless Steel Perforated Sheets Specification

- Surface Treatment

- Powder Coated

- Usage

- Industrial

- Material

- Stainless Steel

- Size

- Standard

- Product Type

- 314 Stainless Steel Perforated Sheets

- Color

- Silver

314 Stainless Steel Perforated Sheets Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About 314 Stainless Steel Perforated Sheets

Stainless steel grade 314 has excellent high-temperature resistance characteristics among the chromium-nickel steels series. The silicon content in this material improves oxidation and carburization resistance.Stainless Steelhas properties like easy formability, manufacturability, corrosion resistant, fire and heat resistance.Stainless Steelhas high tensile strength, temperature resistance, impact resistance, and excellent strength-to-weight ratio.Theperforated sunshades and claddingsprovides privacy for the building residents without any view obstruction while controlling interior climate thus reducing the load of air conditioning and saving energy to a large extent.314 Stainless Steel Perforated Sheetsfences and banisters keep enclosed machines and other properties from damage secure and the safety of people.High Durability for Industrial Needs

The 314 Stainless Steel Perforated Sheets are engineered to deliver enhanced performance in harsh industrial conditions. Their powder-coated surface not only provides an attractive silver appearance but also adds an extra layer of protection against rust and wear, ensuring longevity and minimal maintenance.

Versatile Applications Across Industries

Our perforated sheets serve a multitude of industrial functions, ranging from filtering and screening processes to decorative architectural uses. Thanks to their high strength and reliability, they are especially suitable for environments where both function and aesthetic appeal are required.

FAQs of 314 Stainless Steel Perforated Sheets:

Q: How are 314 Stainless Steel Perforated Sheets manufactured?

A: These sheets are produced using premium stainless steel, perforated through precision machinery to meet standard sizing. The surface is powder-coated to enhance corrosion resistance and provide a consistent silver finish.Q: What are the main uses of 314 Stainless Steel Perforated Sheets in industrial settings?

A: They are widely utilized for filtration, ventilation, screening, and architectural applications in sectors such as chemical processing, construction, and food processing due to their strength and durability.Q: When should I choose powder-coated sheets over non-coated ones?

A: Opt for powder-coated perforated sheets when you require improved resistance to environmental factors like moisture, chemicals, or frequent handling, as the coating adds an extra layer of protection and extends service life.Q: Where can these perforated sheets be supplied or exported from?

A: We supply, export, and trade 314 Stainless Steel Perforated Sheets from India to various regions, ensuring timely delivery and adherence to international quality standards for industrial clients worldwide.Q: What is the process for ordering and acquiring these sheets for industrial use?

A: Customers can contact us directly with their requirements; we assist in selecting the right specifications and manage the supply, export, and delivery processes efficiently to meet industrial project timelines.Q: How does the powder coating benefit the perforated sheets?

A: Powder coating enhances the sheets resistance to corrosion, scratches, and general wear, making them ideal for heavy-duty industrial applications while maintaining a visually appealing silver finish.Q: What makes 314 stainless steel suitable for industrial perforated sheets?

A: Its superior resistance to heat and corrosion, along with remarkable mechanical strength, makes 314 stainless steel particularly effective for perforated sheets used in demanding industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Stainless Steel Perforated Sheet Category

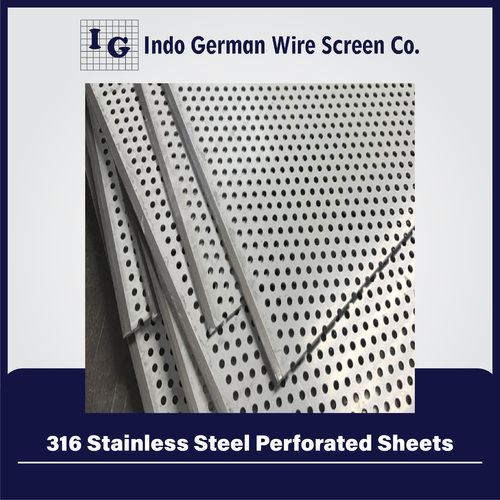

316 Stainless Steel Perforated Sheets

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Other , Polished, Epoxy Coated, Matte or Bright Finish

Material : Other , 316 Stainless Steel

Temper : Annealed

Feature : Corrosion Resistant, Durable, High Strength, Precision Made

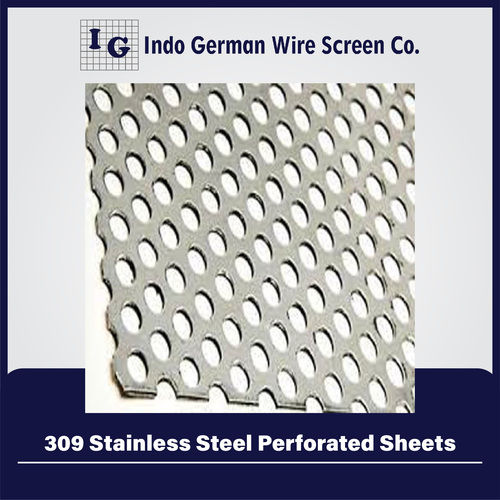

309 Stainless Steel Perforated Sheets

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Other , Polished, Pickled, Annealed

Material : Other , 309 Stainless Steel

Temper : Soft, Hard, Half Hard

Feature : High Temperature Resistance, Corrosion Resistant, Durable, High Strength

330 Stainless Steel Perforated Sheets

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Other , Polished, Matt Finish

Material : Other , 330 Stainless Steel

Temper : Annealed

Feature : Corrosion Resistant, Durable, High Strength, Heat Resistant

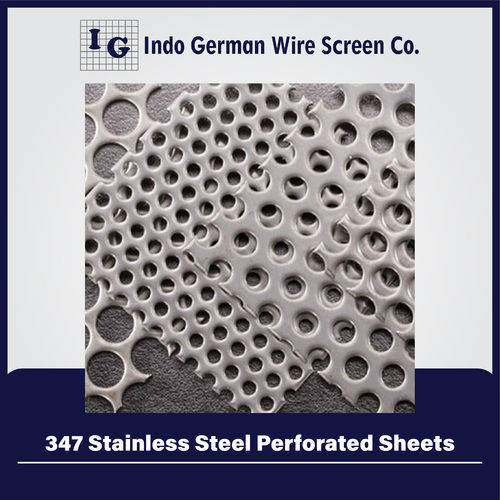

347 Stainless Steel Perforated Sheets

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Other , Polished, Mill Finish

Material : Other , 347 Stainless Steel

Temper : Soft, Hard, Half Hard

Feature : Corrosion Resistant, High Temperature Strength, Excellent Weldability, Durability

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry